Herewith, two metalworking procedures that look like magic.

One: Metal spinning.

Many people are familiar with "spun metal" - you might have a salad bowl or arty lampshade made of "spun aluminium", for instance. But the actual procedure, done by hand on a normal lathe or by automatic machinery, is quite mesmerising:

There's no real upper limit to the size of the objects you can make by spinning. If your lathe can accomodate the initial piece, you can spin larger...

...or much, much larger...

...things.

Two: Skiving.

Skiving is shaving a thin layer off something. I think an ordinary woodworking plane actually more or less qualifies as a skiving tool. It's a standard procedure in leatherworking, but you can do it to metal, too, and that's where it shades over into the miraculous, if you ask me.

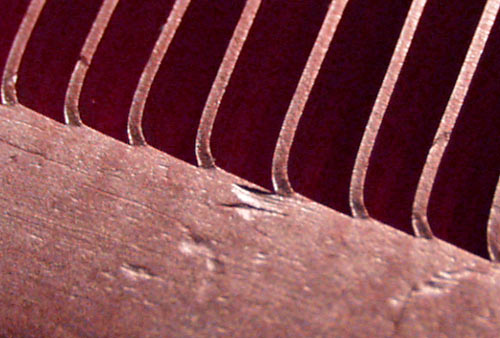

A metal-skiving machine doesn't just carve thin layers off a block of metal, like a plane would. In one stroke, it can cut each slice to a uniform length and leave it connected to the base, standing up parallel to all of the other slices.

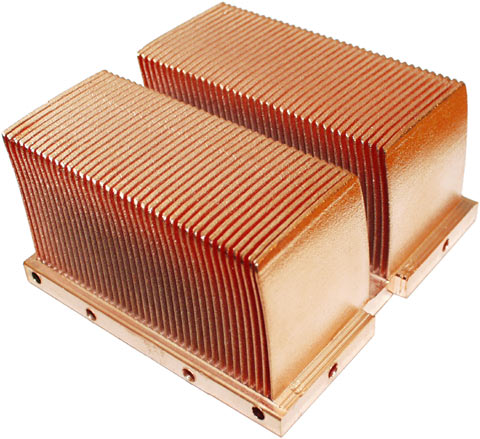

And so, hey presto, you've suddenly got CPU-heat-sink fins like these!

In more detail:

Unfortunately, I can't find a video clip of metal skiving in progress. There's a little picture accompanying the Wikipedia article on skiving machines, but that's all. Do please tell me in the comments if you know of a clip.