Herewith, two metalworking procedures that look like magic.

One: Metal spinning.

Many people are familiar with "spun metal" - you might have a salad bowl or arty lampshade made of "spun aluminium", for instance. But the actual procedure, done by hand on a normal lathe or by automatic machinery, is quite mesmerising:

There's no real upper limit to the size of the objects you can make by spinning. If your lathe can accomodate the initial piece, you can spin larger...

...or much, much larger...

...things.

Two: Skiving.

Skiving is shaving a thin layer off something. I think an ordinary woodworking plane actually more or less qualifies as a skiving tool. It's a standard procedure in leatherworking, but you can do it to metal, too, and that's where it shades over into the miraculous, if you ask me.

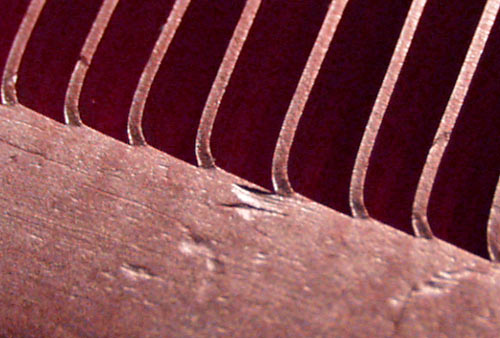

A metal-skiving machine doesn't just carve thin layers off a block of metal, like a plane would. In one stroke, it can cut each slice to a uniform length and leave it connected to the base, standing up parallel to all of the other slices.

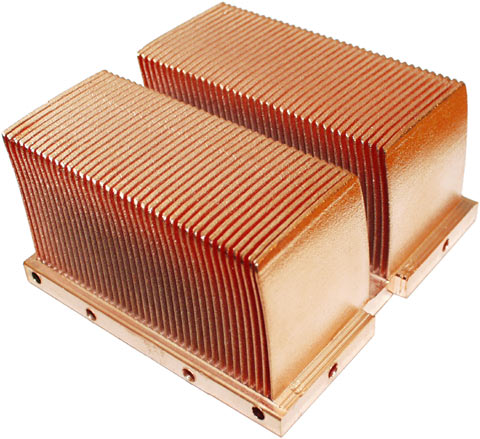

And so, hey presto, you've suddenly got CPU-heat-sink fins like these!

In more detail:

Unfortunately, I can't find a video clip of metal skiving in progress. There's a little picture accompanying the Wikipedia article on skiving machines, but that's all. Do please tell me in the comments if you know of a clip.

27 June 2009 at 6:06 pm

I wonder how the chap in the first video can touch that piece, which seems to be moving quite quickly indeed, touches it without his fingertips catching on fire. Then again, I suppose you build up enough callus, and it doesn't matter much. A buddy of mine plays guitar and has such this callus on his first three fingers that they have no sensitivity at all anymore, he can handle burning hot things with ease.

It does rather remind me of the way they make aluminium ladders, which are extruded at room temperature. The sound of the protesting metal is quite something.

27 June 2009 at 11:13 pm

Too bad there aren't videos of skiving, I've always wanted to see a skiving machine at work. I didn't even know about metal turning though; I learned something new today :)

My favourite metalworking productivity wasters, by the way, are show-off videos of CNC mills and lathes; I find it quite fascinating to see them shape, cut and punch holes into hard steel like it's putty.

You can start from here and here, then go on by related videos. Goodbye, afternoon.

If I were rich I'd live in a repurposed industrial warehouse, in one corner of which would sit a Matsuura CNC mill...

On a related subject, this is quite interesting as well.

And then, there's silliness.

Red October: well, the guy isn't (apparently) pushing very hard against the metal. I don't think it's unfeasible to glide your fingers over a spinning piece of aluminium like that without making excessive heat by friction.

27 June 2009 at 11:17 pm

It's not spinning all that fast. Having spent some time futzing round with a lathe and aluminum, there's a surprising amount of safe hand contact that can occur when working with things like this. I'd be MORE concerned about the carcinogenic effects of long term exposure to the skin of the lubricant he's using. If it's a wax or paraffin, no big deal, something petroleum based? Not so much.

28 June 2009 at 1:45 am

sniglet- most spinners I know use bar soap. Whichever one has the least offensive taste because you do tend to get some thrown off the spinning metal. I like Dial.

28 June 2009 at 4:39 am

Friend of mine repairs old trumpets and sells them on ebay. He's had occasion to have a new bell spun and says he's learning the trade now. Fascinating work.

28 June 2009 at 10:55 am

Blatant self interest disclaimer: I'm on of the QMI consultants who is currently responsible for this machine. ON the other hand, we are a not-for-profit technology diffusion agency.

Incremental Sheet Forming:

http://www.qmisolutions.com.au/article.asp?aid=160

http://www.qmisolutions.com.au/article.asp?aid=223

The concept is metal spinning, but CNC controlled so you can create complex 3d shapes.

Further developments in this field include multipoint (top side and underneath coordinated) and robotic incremental forming.

Australia is lucky - this is one of the very few machines around the world that's open for inspection.

28 June 2009 at 2:15 pm

I'm going to second Change's first link as a must-see: http://www.youtube.com/watch?v=QsmiIeAkE-o

Wait til it gets to about 6:40 to see some insane 5-axis manipulations.

Here's another cool but only slightly related vid:

http://www.youtube.com/watch?v=GlJzD9Hx_zY

http://en.wikipedia.org/wiki/FANUC_Robotics

FANUC use their own robots to manufacture... more robots! Skynet is just around the corner!

28 June 2009 at 3:50 pm

Thanks for the info. I guess the video makes it look much faster than it is.

28 June 2009 at 6:33 pm

Pay me all you want, but I would never touch an object spinning on a lathe. Never. Never. Never. I like my fingers right were they are: attached.

29 June 2009 at 11:14 pm

First video just made me think of a lava lamp

30 June 2009 at 12:08 am

@corinoco

I totally agree. It's like leaving a chuck key sitting in the chuck - I get nervous just seeing it done, even on video.

In normal cutting procedures it would be absolute insanity to touch the part. Too much of a chance that some chip didn't break off the parent part, and would whip around a slice you open like an orange.

Treat machinery with a healthy dose of respect, or it will bite you eventually!

Do you do any machining, Dan?

30 June 2009 at 2:02 am

Spinning is good (and actually quite a bit of fun) but I still like high pressure extrusion forming for simply being impressive - like how aluminium scuba tanks are made. http://www.youtube.com/watch?v=qAgSU6BCpsY The meat there is at about the 1 minute mark.

6 January 2010 at 7:00 am

Please remove Franjo Metal's video (top right of page) ASAP.

We removed it from our website years ago.

Thank you very much.

6 January 2010 at 9:47 am

(I e-mailed this reply to Martin as well as posting it here.)

Um - what is it that's actually wrong with me embedding that Google Video clip on one of my pages?

If you're the copyright-holder and you don't want that clip to be ton Google Video - if someone uploaded it without your permission, or if you uploaded it yourself but have now changed your mind - then you need to contact Google Video about it (or just delete it yourself, if you uploaded it), not complain to people who embed it on their own sites.

I'd be sorry to see it go, since it's a great example of the art (and, I think, good advertising for Franjo Metal Spinning), but if it's copyright to you, you have the right to get Google Video (and/or YouTube, which is also a Google property now) to take it down. I can't help you do that, though!