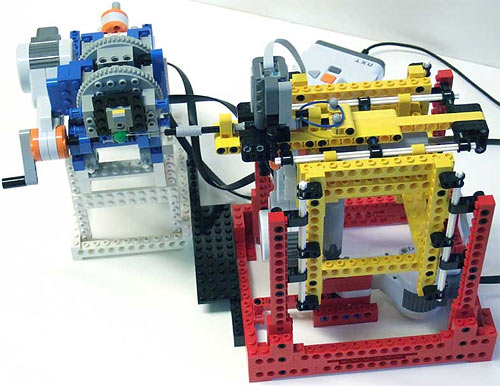

This is a contact-type 3D scanner. Philippe "Philo" Hurbain (co-author of "Extreme NXT", a book about advanced Lego robotics) made it to help him import odd-shaped Lego parts into the LDraw Lego-CAD program.

As you may have noticed, the scanner is itself made out of Lego. I think the only non-Lego parts in it are the actual needle that prods the thing being scanned, and one extra-flexible cable going to a standard NXT light sensor.

All the rest - drive components, sensors, you name it - is 100% Lego. The brain is Mindstorms NXT. Hurbain has made various add-on sensors for Lego robots, but I don't think he's used any of them in this.

Apparently, the new linear-actuator parts are accurate enough for this job, when you drive them with one of the NXT motors, which have built-in position encoders.

More info on Philo's site.

22 March 2009 at 12:52 am

On a similar note David 3D Scanner ( http://www.david-laserscanner.com/ ) allows you to make 3D scans of objects using a laser line level and a webcam. There's a video that, if nothing else, is a fairly good demo of the tech: http://revision3.com/systm/laserscan/

22 March 2009 at 9:30 pm

OK, now combine a 3D Lego scanner with a decent 3D printer and you have infinite Lego.

Such thoughts make me smile.

Back to building theremin...

22 March 2009 at 10:22 pm

3d lego scanner+3d lego printer= lego apocalypse as the world is devoured by self replicating legos.

23 March 2009 at 1:22 am

multicoloured goo...

I got goosebumps

23 March 2009 at 10:53 am

Ooh! A lathe and a milling machine (CNC controlled of course) to create clay moulds. Bake in a kiln (or home oven), then pour your thermoplastic in.

Once you have the hang of soft plastic, try moving up to brass. Your next assignment: a working steam engine, driving a hand-wound alternator.

23 March 2009 at 11:04 am

Lego scanner... Lego printer... self-replicating Lego tribbles!

23 March 2009 at 7:22 pm

In theory it's in fact pretty close to a scanning tunnelling microscope!

But in order to achieve sub-nm precision you'd probably have to replace some of the lego...

24 March 2009 at 9:05 pm

What about using your 3D scanner and printer to bootstrap smaller components?

26 March 2009 at 10:16 am

If you took the laser from a (multi layer) DVD player, could you use feedback from the focus to get depth data?

If it was mounted on the tip of a 15cm pole (for example) could you combine a large gear movement at the far end, with a smaller movement (or even a pivot point) near the laser, to produce scans of a Very Small Area?