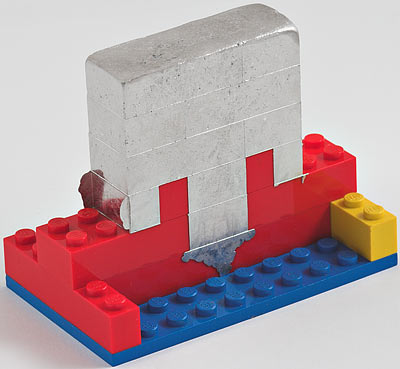

Here's something you don't see every day.

It is, however, exactly what it looks like - a metal casting that's been poured in a mould made of Lego. Plain Lego bricks are, of course, made from ABS plastic, whose melting point is a bit above 200 degrees Celsius.

There are lines on the side of the casting that give the impression that it's made out of bricks itself, but they're from the bricks that moulded it - the metal is all one piece.

You could even make actual metal Lego bricks this way, if you wanted to. Just make a rubber mould of the brick, and pour the metal into that.

The reason why it was possible - easy, in fact - for me to do this without instantly destroying the mould and setting fire to the kitchen is that the metal is Wood's metal, a bismuth-based eutectic alloy. Its melting point is only 70 degrees Celsius, and the "eutectic" part means it melts and freezes as you'd expect a normal substance to, at one temperature, rather than having one component of the alloy remaining solid or liquid while the other changes state.

(I got my Wood's metal on eBay; here's a search that finds a few current sellers of the stuff.)

Anyway, you can melt Wood's metal in boiling water - or in a beaker sitting in some boiling water, which is what I did. Then I just poured it into the mould and left it to sit.

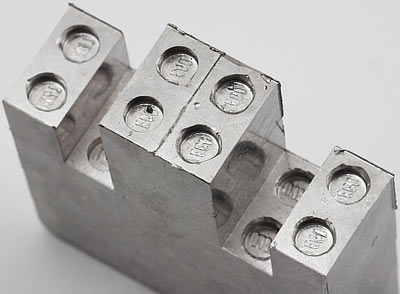

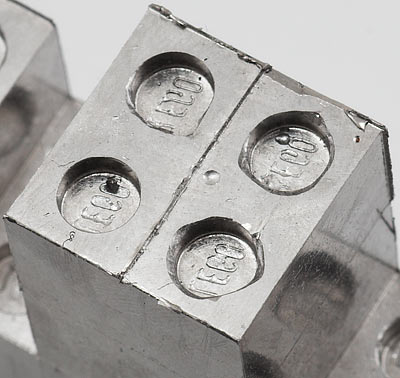

Here's the casting, removed from the Lego and with the bits of flashing where the metal flowed into the gaps between bricks broken off.

Never has a brick separator been more useful. I needed pliers to get the two 2-by-1 bricks out, though.

There are a couple of obvious voids in the side of the casting, because I didn't agitate the mould to bounce bubbles out of it. It's usually a good idea to pre-heat casting moulds, too; the Lego was only at room temperature.

For a first attempt, though, this really isn't bad.

It's close enough that if I wanted to put it back together with the Lego, it'd actually matter whether the "LEGO" stamped on the tops of the blocks was the right way around.

Wood's metal isn't very hard or strong, so you can't use it for most serious casting purposes. Because it's got lead and cadmium in it, you should also be a bit careful with it, though if you wash your hands afterwards and refrain from eating any of it, you should be fine (the other constituents are bismuth and tin, both of which are safe enough; Wood's metal overall is far less dangerous than mercury). But you can still use it for, for instance, casting up temporary holders for odd-shaped things on which you want to perform machining operations, or filling fragile tubes before you bend them. Just pour boiling water over the thing afterwards to get the Wood's metal out.

Back on the Lego kick, Wood's metal is pretty dense, so you could use it to increase the weight of existing bricks. This could come in handy if you were, for instance, competing in a Lego robot sumo contest and didn't have any of the very rare official lead-weighted bricks to make your 'bot heavier. More practically, it's a casting alloy that you could pour into the nose of a model plane, or something, to easily put weight where it's needed.

Wood's metal is easy to buy from metalworking suppliers and on eBay. The stuff I got is allegedly a more precisely measured mixture than the cheaper bulk versions, which may or may not have justified its somewhat higher price; I got it from this eBay dealer, but they don't have any on sale as I write this.

13 December 2006 at 2:07 am

Good ol' Wood's Metal! In my current studies in medical physics, I have come across quite a bit of the stuff. We use a brand called Cerrobend--originally used by plumbers and the like to bend, but not break, pipes--for electron shields!

Well, not exactly an electron shield, but rather to shape the electron beams for patients. The inexpensive way to do a sort of IMRT (or at least conformal) therapy with electron beams. It is quite neat to work with as, if you had a high enough tolerance for pain, you could pour the stuff over your hand. Of course, since it is below boiling for water, the Leidenfrost Effect doesn't work, so you're stuck with ~70 deg. Centigrade stuff stuck to your hand, but it is still quite neat. I've actually been looking around to find large quantities of the stuff, but all I can find on ebay are a few ounces here and there.

13 December 2006 at 6:32 am

Casting metal LEGOs

Daniel writes - "It is possible to cast molten metal in a plastic mould. Even in a _LEGO_ mould. You just have to pick the right metal." - Link. Related: LEGO projects @ MAKE - Link.Lead figure moldmaking and...

13 December 2006 at 3:02 pm

I wonder what reaction would be prevoked if one were to fill someone's home or office keyhole with this metal. While it wouldn't make a key impression or anything, it would make the owner wonder how the heck that happened if they were unfamiliar with this metal.

13 December 2006 at 11:31 pm

Found this through the Make: blog. Fascinating! You're also a fellow Blogsome user, so that gives you two stars in my book. :)

14 December 2006 at 1:33 am

I'm not just a Blogsome user - I'm their current number one Sample Blog, I'll have you know!

I don't know whether this speaks to the excellence of my blog or the crappiness of all of their others, of course.

More MAKE-ey stuff for visitors from the MAKE blog:

Dumb stuff in microwaves, electrolytic rust removal, IR photography, a MAKE product (sort of), sparky stuff, and, of course, The Secret Life of Machines.

14 December 2006 at 2:08 am

You, sir, have too much fun. ;)

14 December 2006 at 10:20 am

Is there such a thing as too much fun?

15 December 2006 at 1:57 am

Touché

26 January 2007 at 8:42 am

How much safer is it, really, than metallic mercury? No question that organomercury compounds are nasty, and that you should keep your mercury in a sealed container, but I'm not sure that metallic mercury is really very bioavailable. Whereas all that cadmium is foul stuff...

6 February 2007 at 1:50 pm

Just a note, those weighted bricks have a piece of steel in them, not lead. Any yes, I did take one of them apart.

14 September 2007 at 8:06 am

Do you think one could make a mold using this metal and then cast Urethane resin into it?

I've read that Woodsmetal, if cast into long strips can be used like solder..if thats true that what are the flow properties of woodsmetal? does it soften as it approaches its melting point or does it stay hard until it gets then then "poof" suddenly becomes fluid like solder does?

ALso, after becoming liquid, how long does it stay like that before it hardens? again using the solder example, it'll return to a solid pretty much as soon as a heat source is removed..